Machining workshop to deliver improved services

AMME has a wide range of machinery consisting of traditional machines, finishing machines but also a machining centre.

Having a team of machine tool operators and a machining workshop is a tremendous asset in our line of business. Indeed, this division, which our competitors often do not have, really differentiates us by giving us unrivalled versatility, flexibility and reactivity.

Internal skills to reduce costs

So that we are able to produce as many parts as possible in-house, we have recently bought a new machining centre and hired a trained machine tool operator. This strategy means we are able to offer you more cost-effective and timely solutions by reducing production costs and developing our internal skills.

In our machining workshop, we also have numerous finishing machines enabling us to be even more independent. With these machines, we are able to cold burnish, grind and sand any type of part.

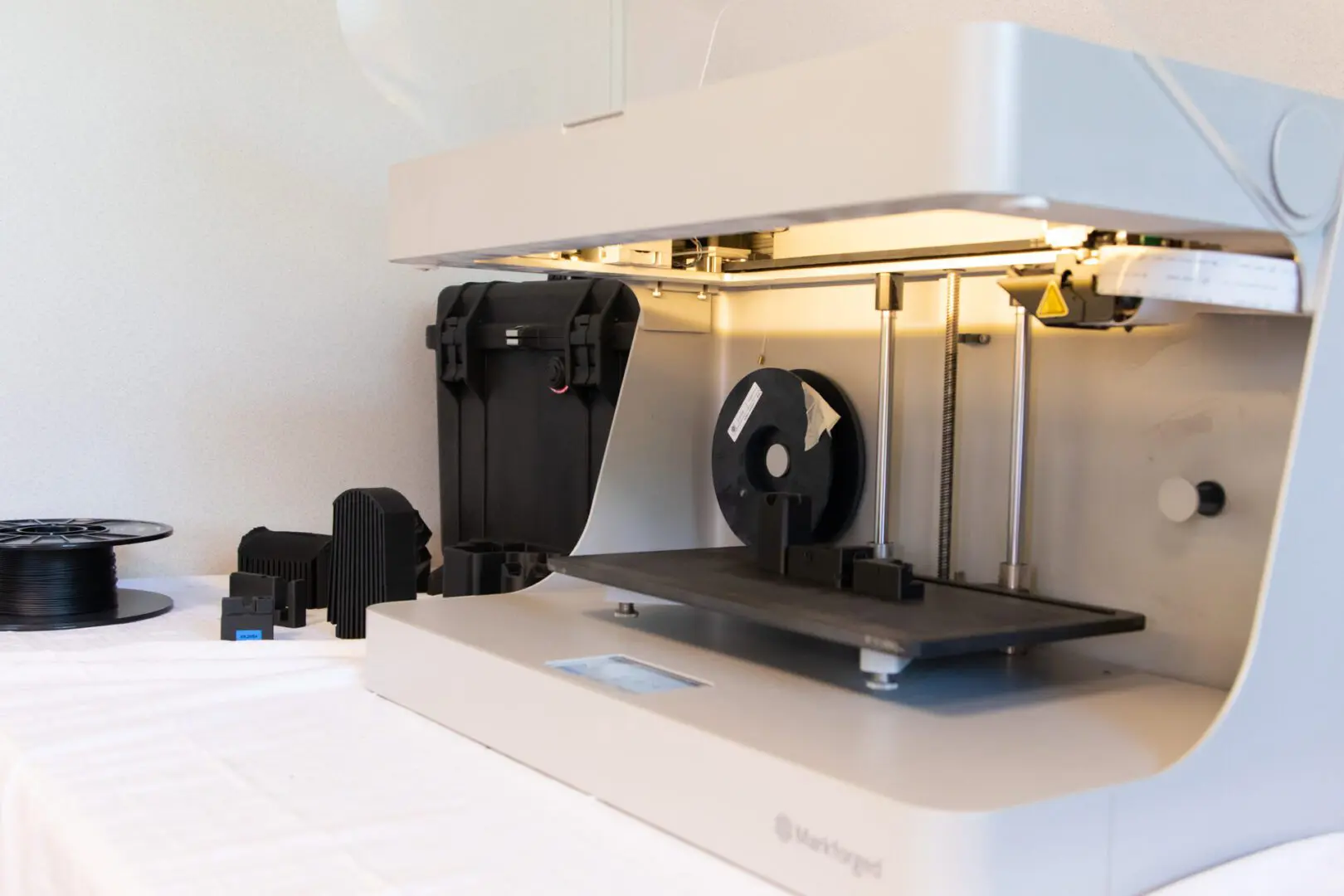

A 3D printer to complete the machining workshop

Among our parts manufacturing solutions, we also have a professional 3D printer (fused deposition modelling) produced by MARKFORGED. This allows us to produce parts in record time (you can print parts over night for the following day). The financial gain from these printed parts over more conventional machining allows us to be even more competitive and offer you ever more attractive prices.

With our technical skills in the field of machining, we are able to support you and offer you the most appropriate, cost-effective and fastest solutions.